►INTRODUCTION TO GRS: GLOBAL RECYCLED STANDARD

GRS certification, the Global Recycled Standard, is an international, voluntary certification system. It mainly sets third-party certification requirements for products’ recycling content, chain of custody, social responsibility and environmental practices, and chemical restrictions. The goal of GRS certification is to promote the use of more recycled materials in products and reduce potential hazards during production.

● Recycling content: stipulates the proportion and type of recycled materials used in products.

● Chain of custody: ensure product tracking and verification throughout the entire process from raw materials to final products.

● Social responsibility and environmental practices: Supply chain manufacturers are required to comply with relevant social responsibility and environmental regulations.

● Chemical restrictions: Restrict the use of certain harmful chemicals in products.

GRS certification was originally developed for the needs of the textile industry to check recycled products or the use of recycled materials in certain specific products. With the increasingly serious global environmental problems and the increasing shortage of resources, the importance of GRS certification has gradually increased. Many national governments and companies have begun to pay attention to the importance of environmental recycling and reuse. Companies certified by GRS can prove that their products comply with global recycled standard, thereby gaining more recognition and competitive advantages in the market.

►WHAT ARE THE GOALS OF THE GRS GLOBAL RECYCLED STANDARD?

►ACCESS CONDITIONS FOR GRS CERTIFICATION

GRS certification applies to any product containing at least 20% recycled material. Starting from the recycling stage, each production stage must be certified and ultimately ends with the final seller in a business-to-business transaction. Material collection and material concentration locations are subject to self-declaration, document collection and on-site visits.

►GRS CERTIFICATION AUDIT POINTS

一、Social Responsibility

● Fire safety (fire hydrants, fire extinguishers, completion acceptance, fire acceptance, fire drills, alarm bells, etc.), water quality report, first responder safety certificate.

● Training and equipment (dedicated to GRS training and GRS equipment).

● Environmental manuals and program documents.

● The raw materials of the product must be certified by GRS.

二、On-site situation

● GRS equipment needs to be labeled with GRS special logo.

● Fire hydrants, fire extinguishers, medical kits, alarm bells, etc.

● GRS production area division.

● All GRS, raw materials, excipients, and finished products must be classified separately.

三、Corporate documents

● All GRS raw materials and excipients have traceability documents.

● Balance sheet: All GRS orders are processed from procurement-production-shipment, and outsourcing is not supported.

● All GRS contracts, invoices, procurement to production processes and warehousing must be recorded.

四、On-site environment

● Three wastes detection (water, electricity, gas).

● Sediment, sludge discharge permit and environmental impact assessment.

● Invoices and usage records used.

● Water treatment certificate (sewage treatment plant testing certificate).

五、Use of chemicals

● MSDS (Chemical Instructions for Use).

● Chemicals need separate warehouses and secondary containers.

● Chemical management system.

● Labor protection supplies and professional operating training records are required.

● Chemical usage records

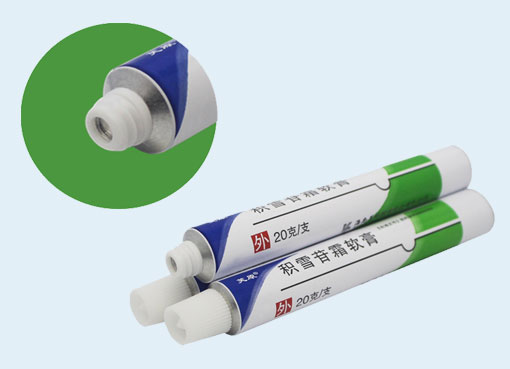

►XINRON OFFERS GRS CERTIFIED ALUMINIUM COLLAPSIBLE TUBES

All tube dimensions shall be in accordance with table 1