Industrial News

Why Aluminum Ointment Tubes are Preferred for Pharmaceutical Packaging

Views : 1261

Update time : 2024-07-18 15:01:06

In the pharmaceutical industry, the packaging of products is just as critical as the formulation itself. Aluminum ointment tubes have emerged as the preferred choice for packaging a variety of pharmaceutical products, including ointments, creams, and gels. Here’s why these tubes are so highly favored in the industry.

Superior Protection and Preservation

One of the primary reasons aluminum ointment tubes are preferred in pharmaceutical packaging is their ability to provide superior protection for the contents. Aluminum is an excellent barrier against light, air, and moisture, all of which can compromise the stability and efficacy of pharmaceuticals. By shielding the product from these external factors, aluminum tubes help maintain the integrity and potency of the medication over time.

Hygienic and Safe

Aluminum tubes offer a high level of hygiene and safety, which is crucial for pharmaceutical products. The tubes are typically lined with an inert coating, such as epoxy or a polymer, that prevents any interaction between the aluminum and the product. This ensures that the medication remains pure and uncontaminated. Additionally, the collapsible nature of aluminum tubes minimizes the amount of air that enters the tube as the product is dispensed, further reducing the risk of contamination.

Tamper-Evident and Secure

Pharmaceutical packaging must ensure the safety and security of its contents. Aluminum ointment tubes often come with tamper-evident seals, providing an added layer of security. Consumers can immediately identify if a product has been tampered with, ensuring that the medication they are using is safe. This feature is not only important for consumer trust but also for compliance with regulatory standards.

Environmentally Friendly

In an era where sustainability is becoming increasingly important, aluminum ointment tubes offer an environmentally friendly packaging solution. Aluminum is highly recyclable, and the recycling process requires significantly less energy compared to the production of new aluminum. Many manufacturers use recycled aluminum to produce new tubes, reducing their environmental footprint. This aligns with the growing consumer demand for sustainable and eco-friendly packaging options.

Lightweight and Durable

Aluminum tubes are lightweight yet durable, making them ideal for both manufacturers and consumers. Their light weight reduces shipping costs and makes them easier to handle during production and distribution. For consumers, aluminum tubes are convenient to carry and use, especially for those who need to apply medication on the go.

Customizable and Attractive

The aesthetic appeal of pharmaceutical products can influence consumer choice. Aluminum ointment tubes can be easily customized with high-quality printing and labeling. This allows for detailed product information, branding, and instructions to be clearly displayed. The ability to create attractive and informative packaging helps pharmaceutical companies differentiate their products in a competitive market.

Cost-Effective

While the initial cost of aluminum may be higher than some other materials, the long-term benefits make it a cost-effective choice. Aluminum tubes offer excellent product protection, reducing the risk of product loss due to contamination or degradation. Their durability means fewer damaged goods during shipping and handling. Additionally, the recyclability of aluminum can lead to cost savings in terms of raw material procurement and waste management.

Versatile Applications

Aluminum ointment tubes are versatile and suitable for a wide range of pharmaceutical applications. They are used for packaging everything from topical creams and gels to ointments and pastes. This versatility makes them a go-to choice for many pharmaceutical manufacturers looking to package different types of products using a consistent and reliable solution.

Conclusion

Aluminum ointment tubes have become the preferred choice for pharmaceutical packaging due to their superior protective qualities, safety, environmental benefits, and versatility. As the pharmaceutical industry continues to evolve, the demand for reliable, sustainable, and effective packaging solutions will only grow. Aluminum ointment tubes are well-positioned to meet these needs, ensuring that pharmaceutical products remain safe, effective, and appealing to consumers.

In summary, the combination of superior protection, safety features, environmental friendliness, and cost-effectiveness makes aluminum ointment tubes an ideal choice for pharmaceutical packaging. They embody the qualities that manufacturers and consumers alike value in ensuring the efficacy and safety of medicinal products.

Superior Protection and Preservation

One of the primary reasons aluminum ointment tubes are preferred in pharmaceutical packaging is their ability to provide superior protection for the contents. Aluminum is an excellent barrier against light, air, and moisture, all of which can compromise the stability and efficacy of pharmaceuticals. By shielding the product from these external factors, aluminum tubes help maintain the integrity and potency of the medication over time.

Hygienic and Safe

Aluminum tubes offer a high level of hygiene and safety, which is crucial for pharmaceutical products. The tubes are typically lined with an inert coating, such as epoxy or a polymer, that prevents any interaction between the aluminum and the product. This ensures that the medication remains pure and uncontaminated. Additionally, the collapsible nature of aluminum tubes minimizes the amount of air that enters the tube as the product is dispensed, further reducing the risk of contamination.

Tamper-Evident and Secure

Pharmaceutical packaging must ensure the safety and security of its contents. Aluminum ointment tubes often come with tamper-evident seals, providing an added layer of security. Consumers can immediately identify if a product has been tampered with, ensuring that the medication they are using is safe. This feature is not only important for consumer trust but also for compliance with regulatory standards.

Environmentally Friendly

In an era where sustainability is becoming increasingly important, aluminum ointment tubes offer an environmentally friendly packaging solution. Aluminum is highly recyclable, and the recycling process requires significantly less energy compared to the production of new aluminum. Many manufacturers use recycled aluminum to produce new tubes, reducing their environmental footprint. This aligns with the growing consumer demand for sustainable and eco-friendly packaging options.

Lightweight and Durable

Aluminum tubes are lightweight yet durable, making them ideal for both manufacturers and consumers. Their light weight reduces shipping costs and makes them easier to handle during production and distribution. For consumers, aluminum tubes are convenient to carry and use, especially for those who need to apply medication on the go.

Customizable and Attractive

The aesthetic appeal of pharmaceutical products can influence consumer choice. Aluminum ointment tubes can be easily customized with high-quality printing and labeling. This allows for detailed product information, branding, and instructions to be clearly displayed. The ability to create attractive and informative packaging helps pharmaceutical companies differentiate their products in a competitive market.

Cost-Effective

While the initial cost of aluminum may be higher than some other materials, the long-term benefits make it a cost-effective choice. Aluminum tubes offer excellent product protection, reducing the risk of product loss due to contamination or degradation. Their durability means fewer damaged goods during shipping and handling. Additionally, the recyclability of aluminum can lead to cost savings in terms of raw material procurement and waste management.

Versatile Applications

Aluminum ointment tubes are versatile and suitable for a wide range of pharmaceutical applications. They are used for packaging everything from topical creams and gels to ointments and pastes. This versatility makes them a go-to choice for many pharmaceutical manufacturers looking to package different types of products using a consistent and reliable solution.

Conclusion

Aluminum ointment tubes have become the preferred choice for pharmaceutical packaging due to their superior protective qualities, safety, environmental benefits, and versatility. As the pharmaceutical industry continues to evolve, the demand for reliable, sustainable, and effective packaging solutions will only grow. Aluminum ointment tubes are well-positioned to meet these needs, ensuring that pharmaceutical products remain safe, effective, and appealing to consumers.

In summary, the combination of superior protection, safety features, environmental friendliness, and cost-effectiveness makes aluminum ointment tubes an ideal choice for pharmaceutical packaging. They embody the qualities that manufacturers and consumers alike value in ensuring the efficacy and safety of medicinal products.

Related News

Why Aluminium Hand Cream Tubes Are the Best Choice

Feb .25.2025

When it comes to packaging hand creams, product developers have several options—plastic tubes, glass jars, pump bottles, and aluminium collapsible tubes. Among these, aluminium hand cream tubes stand out as a superior choice due to their excellent protect

The Hygienic Advantages of Aluminum Pharma Tubes

Nov .25.2024

In the world of pharmaceutical and cosmetic packaging, maintaining hygiene and product safety is paramount. Consumers rely on packaging to protect the integrity of their medications, skincare products, and other personal care items. Pharmaceutical aluminu

7 Benefits of Using Aluminum Pharmaceutical Tubes for Cosmetics

Nov .21.2024

In the competitive world of cosmetics, packaging plays a crucial role in ensuring product safety, efficacy, and consumer appeal. Aluminum pharmaceutical tubes have become a popular choice for cosmetic packaging due to their numerous benefits. Here are sev

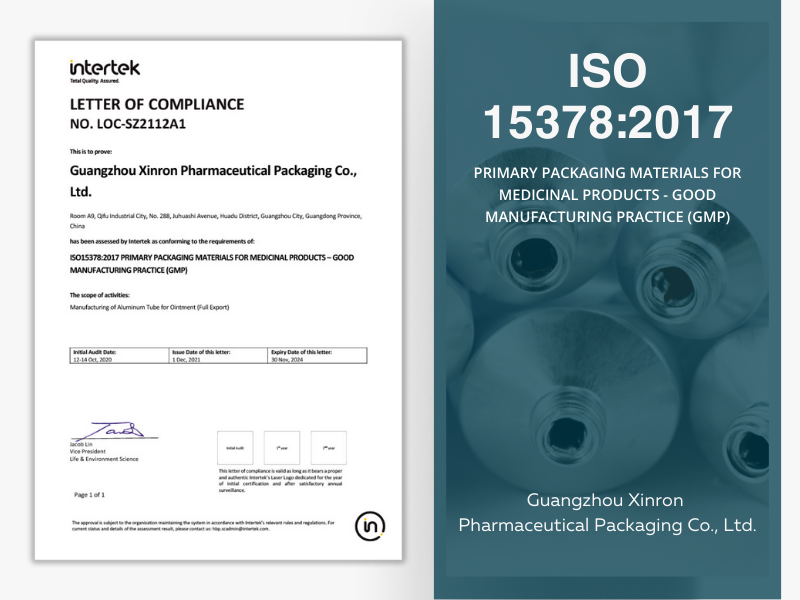

Ensuring Quality and Compliance: Inside Xinron Tube's ISO 15378 Certified Aluminum Tube Manufacturing

Apr .03.2024

In the pharmaceutical industry, ensuring the safety and integrity of medicinal products is paramount. From manufacturing to packaging, adherence to stringent standards is non-negotiable. This is where ISO 15378 comes into play. Let's take a closer look at